Zhejiang customer ceramic block production line cutting system technology transformation project

Project Name

Zhejiang customer ceramic block production line cutting system technology transformation project

Project Time

July 2025

Project Background

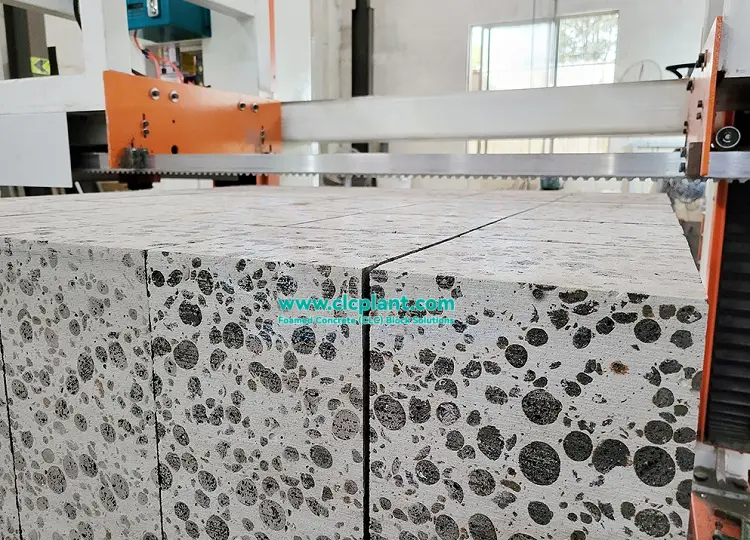

Zhejiang customer's original ceramic block production line cutting machine is inefficient, poor dimensional accuracy, low pass rate, frequent breakdowns and downtimes, resulting in a large number of waste products need to be re-crushed and reuse, production costs and time is seriously wasted. The customer urgently needs to improve the cutting accuracy and production efficiency through technological transformation, to adapt to the needs of multi-category production.

Customer Needs

The customer's core needs include:

-

Solve the problem of lack of cutting accuracy, and control the product error within ±1mm.

-

Reduce the frequency of downtime, improve the stability of the equipment and production efficiency.

-

Support wet and dry cutting process, suitable for ceramic composite bricks, self-insulated blocks and other types of production.

-

Reduce scrap rate, reduce production cost and time waste.

-

Expand the product premium space through technical upgrading, enhance the return on investment.

Project Overview

This project is to carry out technical modification for the cutting system of the original ceramic block production line of the customer, adopting the German CLC wall material equipment technology, combined with localized innovation, realizing fully automatic high-precision cutting, supporting the flexible production of multiple categories, and significantly improving the utilization rate of the equipment and economic benefits.

Project Highlights

-

High-precision cutting technology: Adopting German CLC technology, the cutting error is controlled within ±1mm, which significantly improves the product qualification rate.

-

Fully automatic operation: realize fully automatic wet and dry cutting process, reduce manual intervention and improve production efficiency.

-

Multi-category adaptation: support ceramic composite bricks, self-insulation blocks and other multi-category production, improve equipment utilization rate.

-

Significantly reduce the waste rate: optimize the cutting process, reduce the generation of waste, reduce production costs.

-

Economic benefits: every 1mm increase in cutting precision, product premium space expanded by 5% -8%, high return on investment.

Cooperation process

The company promotes technological transformation in phases:

-

Problem diagnosis and program design: In-depth analysis of the original cutting machine problems, customized technology transformation program.

-

Technology integration and equipment upgrading: adopting German CLC technology, integrating high-precision rotary vertical cutting machine and other advanced equipment.

-

Installation and commissioning and process optimization: complete the installation and commissioning of equipment, optimize the cutting parameters and production process.

-

Operation training and technical support: provide fully automatic operation training and follow-up technical service support.

Project Effect

The project has successfully realized the transformation goal:

-

Cutting accuracy increased to within ±1mm, product qualification rate increased significantly.

-

Significantly reduce the frequency of failure and downtime, and improve production efficiency

-

Support for multi-category production, equipment utilization rate increased

-

Reduced scrap rate, production costs and time waste reduction

-

Expanded product premium space, customer return on investment increased