Customized small size wall panel production line project for Guangdong Shaoguan customer

Project Name

Guangdong Shaoguan Customized Small Size Wall Panel Production Line Project

Project Time

July 2025

Project Background

The customer is a senior building materials enterprise in Shaoguan, Guangdong, and has been deeply cultivating the Jiangxi and Guangdong markets for a long time, which has an important influence in the local industry. In order to meet the demand for wall panels for large-scale farm construction projects in Shaoguan, the customer needs to customize an automated production line for the production of wall panels with specific specifications (1.5 m long, 1.25 m wide and 10 cm thick), which has very high requirements for equipment capacity and product quality.

Customer Needs

The customer's core requirements included:

-

Customized production line for 1.5 m long, 1.25 m wide and 10 cm thick partition boards.

-

Fully automated production process of raw material mixing, mold forming and cutting

-

Meet the high standards of wall panel production and quality for large-scale farm construction projects.

-

Provide trial inspection service to ensure the performance of the equipment and project progress.

-

Relying on the supplier's professional experience, we provide mature and reliable customized solutions.

Project Overview

This project is a highly customized wall panel production line, designed specifically for customer needs, covering the fully automated production process from raw material handling to cutting of finished products, which is the core solution for large-scale, high-quality production of wall panels of specific sizes.

Project Highlights

-

Precise size customization: exactly matching the 1.5m×1.25m×0.1m wall panel specifications required by the customer.

-

Fully automated production: integrated raw material mixing, mold forming, cutting and other processes, reducing manual intervention

-

High-quality guarantee: Strictly control product quality according to the requirements of farm construction projects

-

Trial inspection service: complete the trial inspection before the equipment leaves the factory to ensure reliable performance.

-

Rapid response delivery: efficiently complete the equipment customization, production and delivery to ensure the project progress.

Cooperation process

The company promotes the project in stages:

-

Demand docking and program design: detailed communication of customer demand, customized production line technical solutions

-

Equipment customization and production: manufacture equipment according to customized specifications and integrate automated production process.

-

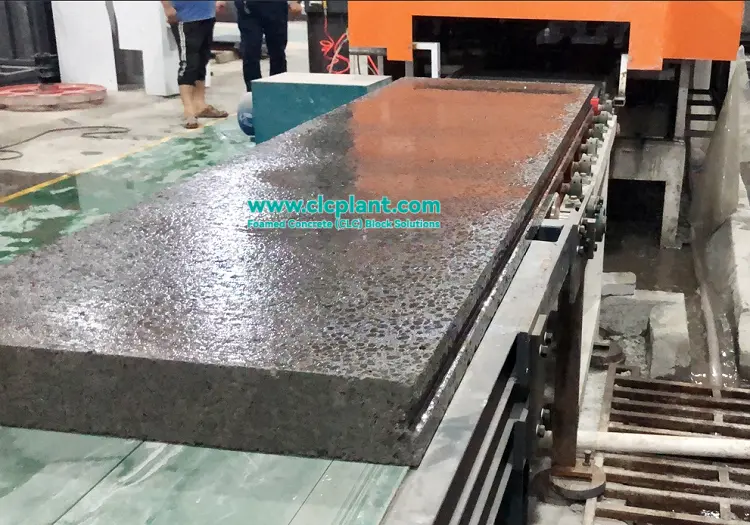

Trial inspection: the customer to the factory acceptance of the equipment trial, to ensure that the performance of the standard

-

Shipment and Installation: The equipment is shipped on time and is currently in the installation and commissioning stage.

-

Follow-up service preparation: installation guidance, operation training and production support will be provided.

Project effect

The project is expected to achieve the following results:

-

Fully meet the customer's demand for automated production of specific wallboard sizes.

-

The output and quality of the wall panels will meet the requirements of the farm construction project.

-

Fully automated production to increase efficiency and reduce labor costs

-

Strengthen the customer's ability to supply the local building materials market

-

Provide a successful example for similar customized projects