Foam bricks: a comprehensive analysis of lightweight and environmentally friendly building materials

I. What is foam brick?

Foam bricks are a lightweight, porous concrete material formed by the cement foaming process, and are so named because of their internal honeycomb structure. It should be noted that the foam brick is not made of Styrofoam, but because of its porous and lightweight properties, it is able to float on the water surface, and its texture is as light as that of foamed bread, so it gets this name.

Main Characteristics:

-

Light weight and high efficiency: small density, light weight, reduce the weight of the building.

-

Thermal insulation: porous structure provides excellent thermal insulation performance.

-

Sound insulation and noise reduction: effectively blocking the spread of sound

-

Fireproof and flame retardant: good fireproof performance

-

Environmental protection and energy saving: utilizing industrial waste, in line with the requirements of green building.

Raw materials of foam bricks

Foam brick production uses a variety of raw materials, mainly including:

Main raw materials:

-

Cement

-

Fly ash

-

River sand

-

Stone powder

-

Tailings slag (optional)

-

Aerated powder slag

-

Blast furnace slag

Environmental advantages:

Variety of raw materials, low production costs, mainly using local waste for production, fully in line with national environmental protection policies and the development of circular economy requirements.

Third, the production process

Foam brick production process is rigorous, mainly including the following links:

Main production steps:

-

Feeding: precise proportioning of various raw materials

-

Stirring: mixing the raw materials evenly

-

Pouring: injecting into the mold forming

-

Foaming: forming a porous structure through chemical foaming

-

Demolding: Demolding after initial molding

-

Cutting: Precise cutting according to specifications

-

Maintenance: Ensure the product reaches the designed strength

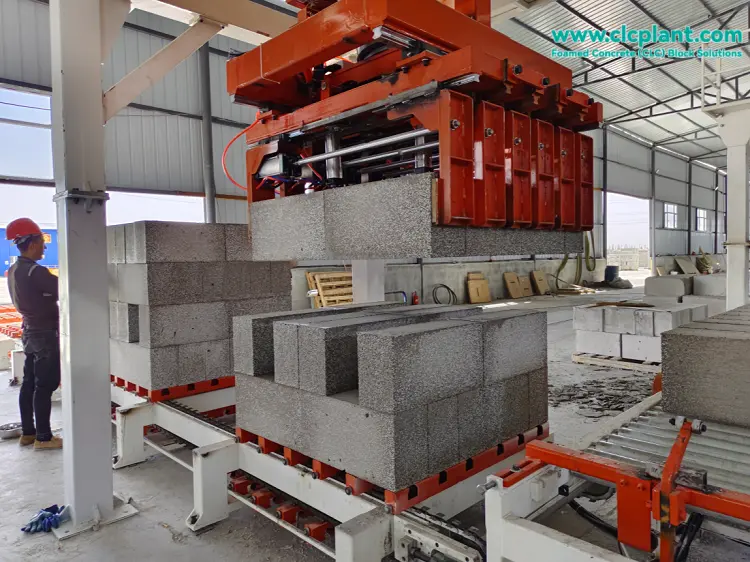

Equipment and technology advantages

Our foam brick equipment production line introduces advanced CLC technology and equipment from Germany, and after localization, improvement and perfection, combined with the actual situation in China, we have developed a set of mature, mass-production, practical and full-automatic foam brick production line.

Equipment features:

-

Annual production capacity: ranging from 50,000 to 200,000 cubic meters to meet the needs of different scales

-

Multi-functionality: by replacing molds and adding auxiliary equipments, it can produce a variety of building material products.

-

Advanced technology: adopting full automatic control system to ensure stable product quality.

-

Strong adaptability: production line configuration can be customized according to customer needs

Product types can be produced:

-

Lightweight bricks

-

Aerated bricks

-

High-precision waterproof wall panels

-

Foamed ceramic blocks

-

High precision waterproof blocks

-

Self-insulating blocks

V. Application value of foam bricks

Building application:

Widely used in the inner and outer walls of frame shear walls and non-framework columns, effectively relieving the overall net weight of the building, while providing excellent thermal insulation and heat preservation and sound insulation and noise reduction.

Comprehensive Advantages:

-

Adaptable: wide source of raw materials, does not take up arable land resources

-

Convenient production: mature production process, high production efficiency

-

Resource utilization: fully utilize local resources and industrial wastes

-

Convenient construction: masonry is convenient and flexible, improving construction efficiency.

-

Economic benefits: reduce the weight of the building and lower the construction cost.

-

Functional Improvement: Significantly improve the function of the building

Environmental protection and social benefits

Foam brick, as a new type of wall material, is in full compliance with the national energy saving and emission reduction and green development policy:

-

Large amount of industrial waste is utilized to realize resource recycling.

-

The production process is energy-saving and environmentally friendly, low-carbon and green

-

Long service life of the product, reducing the generation of construction waste

-

Help to promote the green transformation of the construction industry

Foam bricks are becoming the material of choice for modern buildings with their excellent performance and environmental characteristics. With the deepening of the green building concept and the promotion of environmental protection policies, the market demand for foam bricks will continue to grow. Choosing foam bricks is not only choosing a kind of high-quality building materials, but also choosing a kind of environmentally responsible construction method.

Our company is committed to the research and development and manufacture of foam brick production equipment, providing a full range of services from equipment supply to technical guidance. We welcome interested customers to contact us for more product details and technical solutions to jointly promote the development of green building.