Investment in lightweight brick production line: open a new era of environmental protection building wealth

In the era of green building and industrial solid waste resource utilization wave, lightweight brick with its lightweight, high strength, thermal insulation, sound insulation and fire prevention of excellent performance, is rapidly replacing the traditional building materials, the market outlook is extremely broad. Investment in a high degree of automation of lightweight brick production line is not only to grasp the market trend of the wise move, but also to enter the multi-billion emerging building materials market is a key step.

Why choose lightweight bricks? --The double driving force of policy and market

-

Green: mainly use fly ash, slag and other industrial solid waste, waste into treasure, enjoy the national environmental policy support.

-

Strong demand: Widely used in assembly building, frame structure exterior wall filling, indoor partition wall and other fields, demand continues to rise.

-

Significant benefits: Compared with traditional clay bricks, the production cost is lower, the added value of the product is higher, and the return on investment is considerable.

Core production process revealed: eight steps to create high-quality products

A mature and stable lightweight brick production line transforms raw materials into high-value products through a highly automated process:

-

Accurate feeding: the automated batching system realizes accurate measurement and delivery of a variety of materials to ensure the stability and consistency of the product formula.

-

High-efficiency mixing: High-speed mixer fully mixes the raw materials such as cement, lime, fly ash and water to form a uniform slurry, which lays the foundation for foaming.

-

Mould Pouring: The stirred slurry is precisely injected into molds of different specifications to flexibly meet the diversified order requirements of customers.

-

Constant Temperature Foaming: Under the environment of strictly controlled temperature and time, through physical or chemical foaming process, a stable and uniform closed pore structure is formed, which is the core of "light" and "heat preservation" of lightweight bricks.

-

Static demolding: After initial maintenance in the mold and reaching the predetermined strength, the billet will be demolded automatically and enter the next process.

-

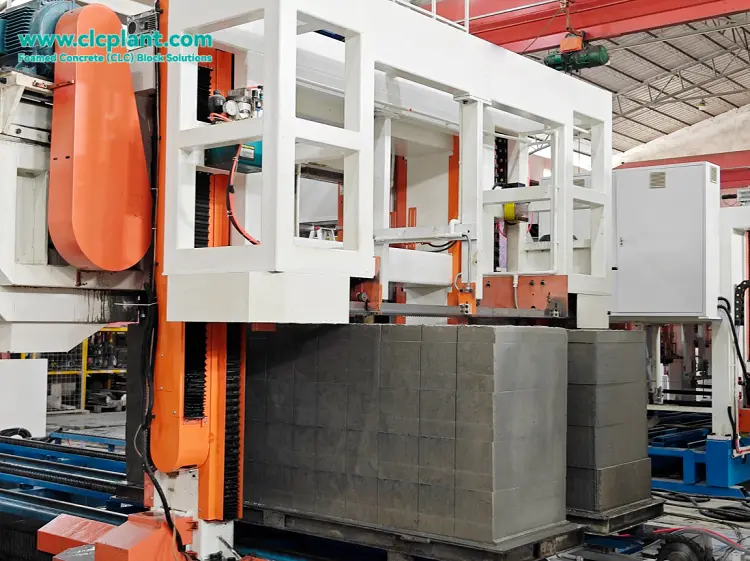

Intelligent Cutting: Adopting advanced CNC cutting machine, the large volume of blanks will be accurately cut into various specifications of blocks or panels with precise size and high yield.

-

Automatic palletizing: the robot or palletizer will automatically palletize the finished bricks on the maintenance truck, ready for maintenance, which greatly saves manpower and improves efficiency.

-

Scientific curing: 2-3 days of static curing in constant temperature and humidity curing kiln, or 7-10 days of natural curing, so that the product reaches the factory strength, stable and reliable performance.

By choosing our equipment, you will get the following guarantees:

-

Whole line turnkey project: from planning, equipment supply to installation and commissioning, technical training, we provide one-stop solution to help you put into production quickly.

-

Advantage of core technology: unique foaming and cutting technology ensures the perfect balance of density and strength of the product, and the quality is ahead of the industry.

-

Low cost and high return: high degree of automation of the production line, low labor cost; low energy consumption per unit of product, significant long-term operational benefits.

-

Lifelong technical support: we are not only an equipment supplier, but also your long-term partner, providing continuous technical upgrading and after-sales service support.

Act now to seize the golden opportunity of green building materials!

If you are looking for lightweight brick production equipment with high stability, high efficiency and high return rate, we sincerely invite you to visit us. Please leave your contact information, we will provide you with a detailed project plan and quotation in the first time.